FC43® Panel Fastener Design Selection for Components

Stud configuration

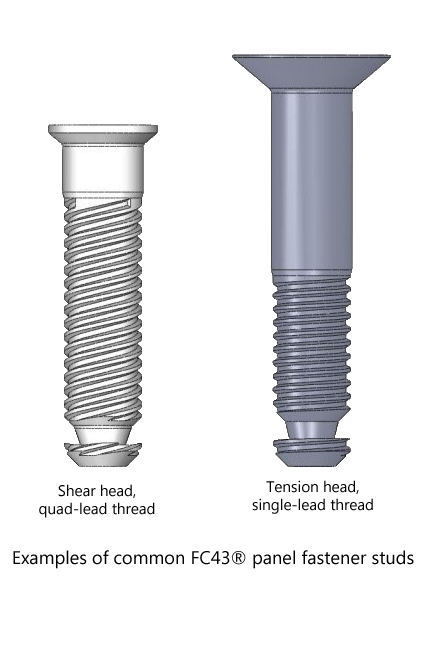

The only requirement that the FC43® fastening system places on the stud is the presence of an annular groove on its tip. Stud material, head style, head dimensions, wrenching recess, thread configuration, thread engagement and grip lengths can be independently defined for different applications. Since no slots or holes are required for the stud, an externally threaded configuration is preferred for providing best mechanical properties for a given hole size.

For stud material selection, the common options are alloy steels such as AISI 4140 or AISI 8740, and stainless steels, such as A286 CRES. This provides the system with great flexibility for providing the proper material configuration for each situation.

Panel fasteners are often located on the aircraft exterior and tend to be configured with countersink heads. Usually, head sizes are adjusted based on loading and bearing conditions and also on panel thickness. The FC43® fastening system can use studs with virtually any head style and size: from large tension heads for load critical applications to 130o countersink heads for thin, soft composite panels. There is also the possibility of using studs configured with protruding heads, for internal panels and other special applications.

As for thread configuration, this is one of the items where the FC43® panel fastener benefits the most from its modularity. Usually panel fasteners are configured with multi-lead threads, for speed of operation. Dual lead threads is the most common option, but the FC43® fastener stud can also be configured with single lead threads. Also, thread length and thread engagement can be fully adjusted to suit specific needs, without interfering with the retaining system in any way.

High strength stainless steel like A286, with a shear head, TORX® recess and dual lead thread are the most common choices for a FC43® panel fastener stud configuration.

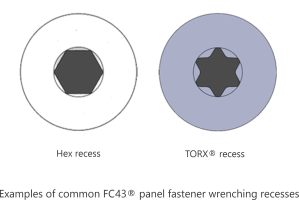

Recess style

With the stud head configuration, comes the choice of recess style. In this regard, the FC43® panel fastener is also completely independent of recess choice. Stud bolts with a TORX® recess are available for those applications where greater fastener torque is required.

Retainer assembly

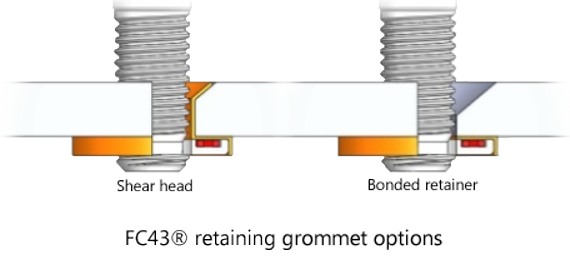

The main function of the FC43® panel fastener retainer is to captivate the stud to the panel and it can be configured in several ways to perform this and additional functions. If no hold-out is required, the retainer assembly can be configured to float on the back side of the panel, performing as a simple retaining ring.

If hold-out capability is required, the retainer assembly has to be captivated to the panel. The most common way to obtain this captivation is by configuring the retainer assembly as a flare-in-place grommet. The flare-in-place grommet option is only suitable for shear head studs.

If the hole diameter is critical and cannot accommodate the grommet wall thickness, the retainer assembly can be adhesively bonded directly to panel.

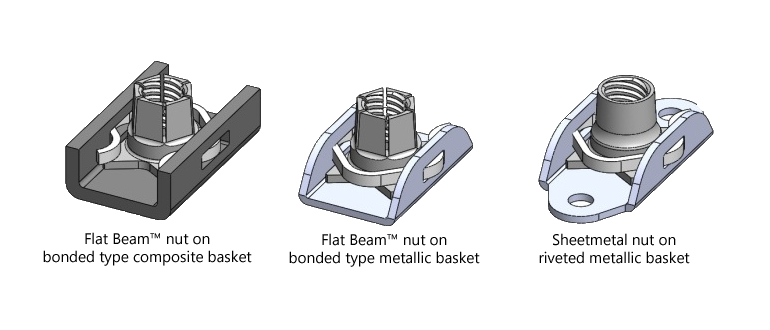

Nutplate configuration

As the FC43® fastening system employs an externally threaded stud, it can be configured to use a multitude of nutplates. The natural choice is to take advantage of the large variety of existing aerospace nuts and select the most adequate for each particular application. Most notably is the full compatibility of the FC43® panel fastener stud with the nutplates used by its well established predecessor, the Mark IV™ panel fastener.

The fact that nuts and stud configurations can be paired with virtually no restrictions gives the system great flexibility and adaptability to diverse operating conditions found in aerospace applications, broadening its scope of usage beyond the realm of regular panel fasteners.

TORX is a registered trademark of Acument Intellectual Properties, LLC.